When industries need high performance, they look for innovation in different ways. One of the oldest and most successful innovations is the external motor, which is versatile in most industries. All the household, commercial, and industrial sectors rely on high-performance motors for daily-life machines. From a washing machine to an entire turbine, one component is shared by all of them, and that is the external motor. All the benefits they offer make them versatile in each industry, whether it is robotics, mechanics, or household goods.

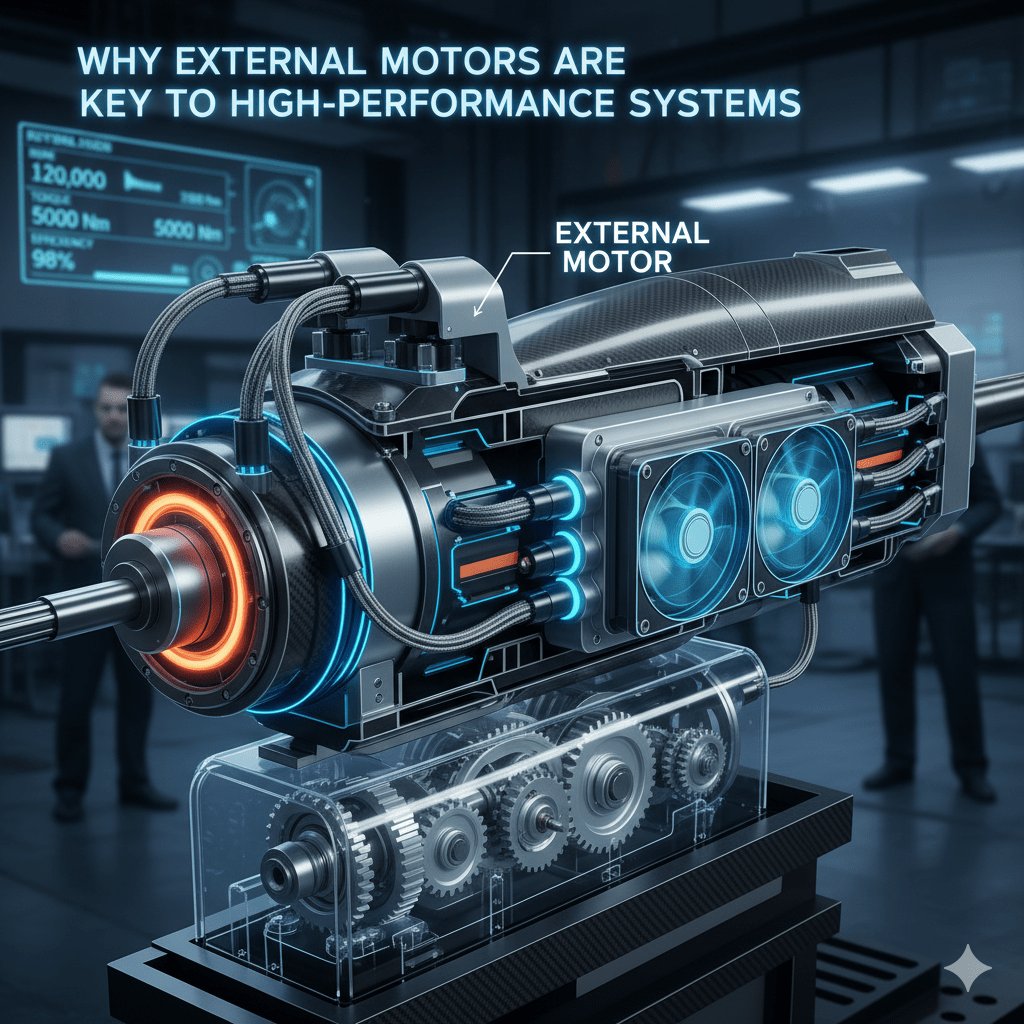

Many machines can’t work unless external motors are installed in them. Whether they are simple fans or turbines, they all need a magnetic system that propels the wings of any machine. The motor attached in it has a magnetic system that contains copper coils for consistent formation of magnetic force. That force helps the propeller to keep moving until it is turned off. The energy formation is angular here, and the entire process depends on the external motors installed in various machines. Their benefits are many, but some are prominent.

Until an immense magnetic force is applied, it is not possible to keep a propeller rotating. Super torque generation is done through external motors in the desired machines. Engineers have to design such motors for efficient rotatory movements. These movements are angular and in an equilibrium state for consistent results.

What they do is install high-performance motors for super-torque generation. The number of coils and various other factors affect the torque generation. The size and quality of motor components decide how much torque will be generated. Therefore, every size of external motor in various sectors meets users’ requirements. Tiny devices and large machinery all need something rotatory to get the work done.

These motors are usually small, but their impact is massive. A medium-sized external motor can handle massive load for propelling functions. They can deal with environmental pressure to rotate in the designed direction. Therefore, industrial exhaust fans and other rotatory devices work well through external motors. It is one of the external motor benefits that comes through its compact size. No matter how small this motor is, it can shift the power pretty well.

HVAC systems, washing machines, robotics, and elevators are some of the widely used machines in the world. All of them contain external motors to perform consistent operations without showing any strain. They are good at handling excess loads in many conditions without showing any signs of damage.

Even electric vehicles contain external motors, and you can call these motors the heart of EVs. There is no engine in them but these motors. Carrying an entire vehicle requires lots of force, and external motors are good at it. The magnetic force they generate through electricity is immense. The swift and efficient energy conversion in EVs makes them suitable for regular use. That is why their motors play a crucial role in handling the challenging loads.

Likewise, household machines and power tools are incomplete without external motors. They keep the force active throughout the use. Whether someone is using a drill machine or a sewing machine, they all contain these motors for consistent movement in a specific direction.

One of the biggest external motor benefits is their high power-to-weight ratio. Even a small motor can handle more weight than its apparent capacity. These motors may seem compact and sophisticated, but they can bear more load than you can imagine. This high power-to-weight ratio helps external motors accelerate machines faster. EVs and power tools are the biggest examples of it. They can perform faster operations through significant magnetic force formation.

That is why both industrial and domestic sectors can rely on these motors. They can’t collapse unless a very excessive load is imposed on them. Since a motor is the heart of most machines, it has to be able to bear more power-to-weight capacity.

They contain lots of coils in them for massive magnetic force generation, and the movement is pretty rapid. You might think that these high-performance motors also cause lots of vibration, but that’s rare. Their structure is manufactured in a way that helps them to prevent vibration. Even if there is any vibration, it is very low, or there is a problem with the external motor. They have a specific alignment that prevents a massive risk of vibration and premature wear and tear.

Likewise, each plate inside the motor and the coils coordinate with the others. They generate force without causing any trouble to the system. That means the wear and tear can not take place unless there is an alignment issue. So, as far as the components are aligned, they can not face any risk of internal damage.

Then there is another significant advantage, which is heat dissipation. The external motors are designed in a way that they dissipate heat when they generate energy. That is a combination of two advantages. This heat dissipation keeps them less hot in intense movement as long as the machines run. Therefore, there is less risk of overloading and coil burning.

Less heat generation keeps the motors safe from early replacement since there is less risk of damage. Turbines, EVs, washing machines, and every similar machine need heat dissipation for long-term survival. They are the machines that have to generate lots of power. Unless they generate that power, they can’t generate acceleration. Therefore, acceleration becomes safe for EVs since the external motors inside them keep dissipating the heat all the time.

External motors are the heart of most machines, and there is a reason behind that. They perform the primary function of propelling a wing, wheels, or anything that needs angular movement. The complex winding system of copper coils helps them keep moving the entire angular mechanism. Their high power-to-weight ratio makes them the perfect choice for rotational movement with acceleration. That’s why the entire EV industry relies on these motors.